duMONT Broach Keyway Broaching Tools Manufacturer

duMONT broach keyway tools deliver the kind of clean, confident cuts machinists rely on when precision isn’t optional. Engineered from high-speed steel and built to stay sharp, they glide through tough materials while holding tight tolerances that keep production on spec. Their tapered, tooth-accurate design turns complex keyway work into a smooth, repeatable operation—whether on a bench-top press or a full production line.

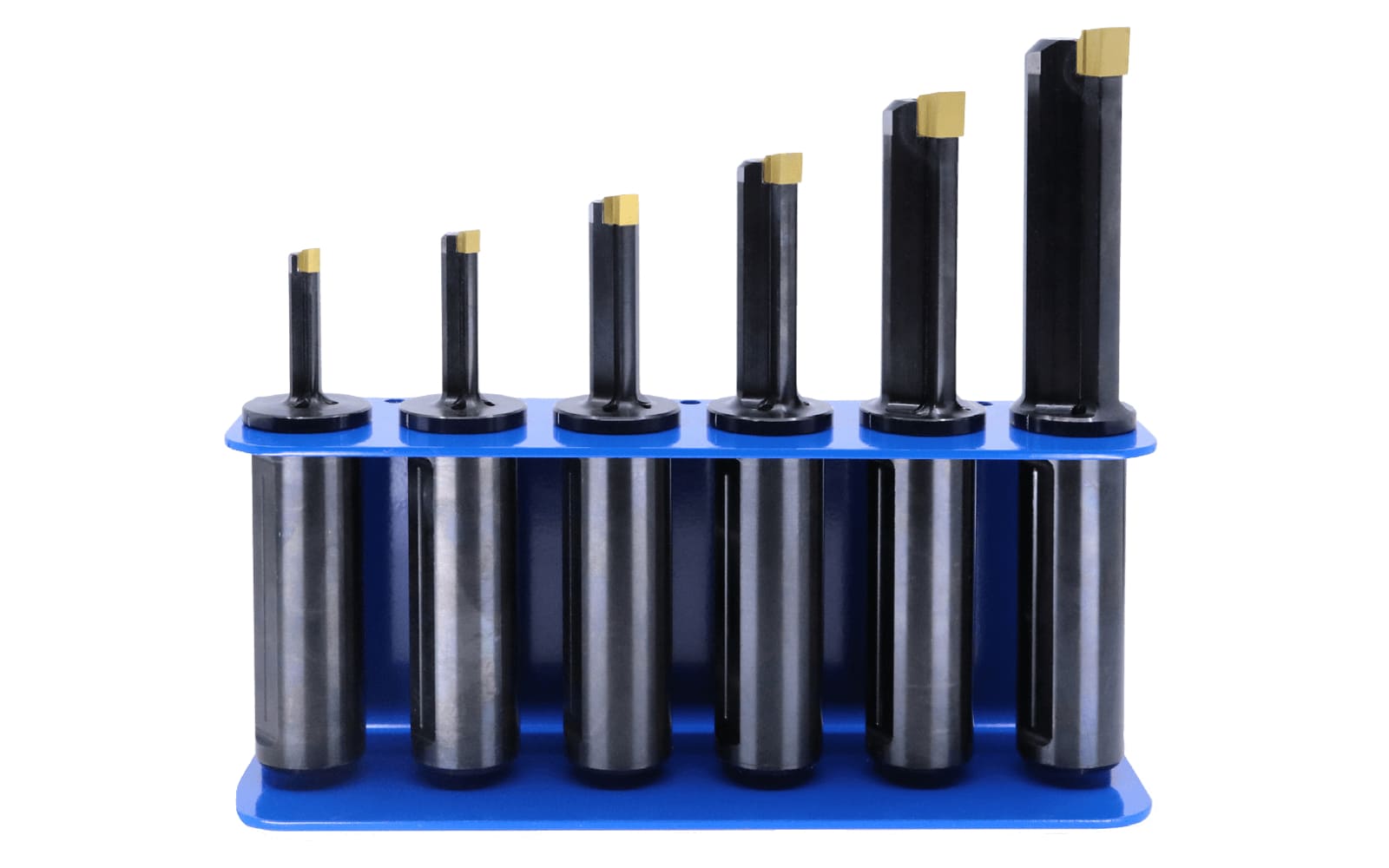

Top duMONT Broach Keyway Broaching Tools

DuMONT Minute Man 13‑Piece Standard Keyway Broach Set #10

A comprehensive Imperial (inch) broach set that includes 9 broaches and 44 bushings for a wide range of keyway applications.

DuMONT Minute Man 15‑Piece Metric Keyway Broach Set #80 (10‑14 mm)

A large metric set in style D that provides 36 possible keyway combinations, ideal for production or maintenance work.

DuMONT Minute Man 5‑Piece Metric Keyway Broach Set (2‑3 mm)

A compact, high-precision set for small keyways, perfect for tight bore machining or prototyping.

duMONT Minute Man tools bring industrial machining to life with precision-engineered broaches built to cut cleaner, faster, and more reliably across demanding applications.

Keyway Broach Sets

Engineered for versatility in both American Standard and Metric sizes, these sets equip machinists with dependable options for cutting accurate keyways across a wide range of bore diameters.

Push-Type Keyway Broaches

Designed for smooth, controlled cutting, these broaches pair with arbor or hydraulic presses to deliver consistent keyways with minimal setup time.

Pull-Type Keyway Broaches

Optimized for heavier-duty applications, pull-type designs provide enhanced accuracy and longer engagement for deeper or more demanding cuts.

One-Pass Keyway Broaches

Perfect for smaller batches, these broaches cut full-width and full-depth keyways in a single stroke, dramatically reducing cycle time.

Keyseating Broaches

Built for internal shaping tasks, these tools deliver clean, straight slots ideal for power transmission and precision-fit components.

Hexagon Push Broaches

Created for forming hexagonal profiles within drilled holes, these broaches simplify socket and drive-feature production.

Bushings for Keyway Broaches

Sized for numerous bore diameters, these bushings ensure guided, accurate broaching by holding the broach perfectly aligned.

Custom Broaches

Tailored for firearm manufacturing, heavy equipment, power transmission, and more, these specialty tools support complex, high-tolerance applications.

Industrial, Rotary & Specialty Broaches

From surface broaching to internal form shaping, these advanced tools expand capability for shops tackling unique or non-standard machining needs.

Reviews

Michael Turner

I’ve worked in a mid-volume machine shop for over a decade, and the duMONT Minute Man broaches consistently outperform every alternative we’ve tested. The push-type keyway broaches cut with an incredibly smooth feel, and the bushings keep everything tracking dead straight. Even when we switch from steel to non-ferrous materials, the edge retention holds up better than expected. After hundreds of cycles, the consistency is still spot-on, saving us time on rework and inspection.

Sandra Martinez

Running production for power-transmission components means tolerances are tight and repeatability is everything. Our custom duMONT broaches were a game changer. The moment we installed them, we saw reduced chatter, cleaner chip evacuation, and a sharp drop in tool failures. What impressed me most was the precision on longer pulls—no drift, no taper, just clean, uniform slots every time. These tools easily paid for themselves within the first two months of heavy use.

Ethan Reynolds

I manage prototyping for a firearms manufacturer, and one-pass broaches from duMONT have become essential to our workflow. Getting full-depth keyways in one motion without sacrificing accuracy is huge when iterating multiple design versions in a single day. The HSS durability means we can push them hard without worrying about premature wear. It’s rare to find tooling that speeds up R&D without compromising finish quality, but these absolutely deliver.

duMONT Broach FAQ

What materials can duMONT broaches cut?

duMONT broaches are designed to handle a variety of materials including steel, cast iron, non-ferrous metals, and some plastics, making them versatile for most machining tasks.

Are duMONT broaches compatible with both metric and Imperial keyways?

Yes, duMONT offers both American Standard (Imperial) and Metric broach sets, allowing users to work with a wide range of key and shaft dimensions.

Can I use duMONT broaches in manual presses?

Absolutely. These broaches are compatible with hand-operated arbor presses as well as hydraulic presses, suitable for both small-scale and production environments.

Do duMONT broaches require shims or bushings?

Most sets include the necessary shims and bushings to maintain accurate cutting paths, though some production broaches are designed to operate without them for faster repeat runs.

How long do duMONT broaches typically last?

Constructed from high-speed steel with a hardness of 58–60 RC, duMONT broaches are highly wear-resistant and maintain sharpness over extended use, especially when used on recommended materials.

Can duMONT provide custom broaches for specialized applications?

Yes, duMONT manufactures custom broaches for firearms, power transmission, heavy equipment, and other industrial applications requiring high precision.

Where are duMONT broaches made?

All duMONT Minute Man broaches are manufactured in the United States, ensuring consistent quality and reliability.